lag time calculation autoclave validation|autoclave steam sterilization lag time : specialty store The maximum load validation would be performed with no added hold period in each vacuum pulse and proven acceptable with physical and biological data (see Figures 3A and 3B). Next, the time required to draw the . $7.99

{plog:ftitle_list}

Autoclaves are also known as steam sterilizers, and are typically used for healthcare or industrial applications. An autoclave is a machine that uses steam under .

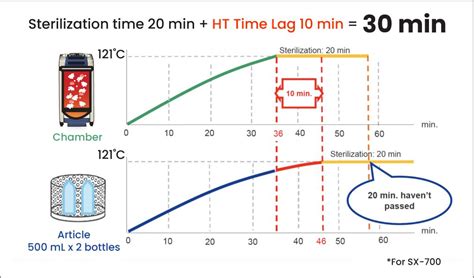

Lag Time: The time dealay between the first sensor reaching the set temperature to the time by which all the sensor reaching the set temperature. Equilibrium time is the time by which all the sensors attains the set .The equilibration time of an autoclave is defined as the period of time that elapses between the attainment of the sterilization temperature at the reference measurement point of the autoclave chamber and the attainment of the sterilization temperature at all measurement probes within the dry goods load placed within the autoclave during a sterilization cycle.The equilibration time is . The maximum load validation would be performed with no added hold period in each vacuum pulse and proven acceptable with physical and biological data (see Figures 3A and 3B). Next, the time required to draw the . Record the temperature and lag time of each probe as per Annexure –1 & 2. . how can we justify thermocouple location in the autoclave and based on chamber volume how can we calculate the thermocouples .

what is lag time in autoclave

latency in autoclave

Beside some guys use autoclave drain control probe for calculation of equilibration time, my opinion is that people make mistake when position TC near control autoclave drain.F0 Calculation Theory and Data Analysis; . Exposure Time – An equipment based parameter that is the time at which the autoclave is held at the desired operating temperature. D-value – The D value is defined as the time in minutes at a given set of parameters required to reduce the population of a biological indicator (BI) by one log . Equilibration time of an autoclave is defined as the period of time that elapses between the attainment of sterilization temperature at the reference measurement point of the autoclave chamber and the attainment of sterilization temperature at all measurement probes within the dry goods load placed within the autoclave during a sterilization cycle. Equilibration .

Calculate the F0 value using the formula F0 = 10^((Measured temperature – 121.1°C)/10) multiplied by the time interval of dwell time to meet all requirements. First, list the number of loads to be validated in the autoclave and categorize them into porous, non-porous, and mixed loads. Categorization is based on the nature of load items like .

results with cycle paraments shown by validation. . •Items were double bagged in autoclave pouches •Wireless temperature sensors we placed into each of . during the hold time was performed. •Items with lower F0 was considered “worst-case”. •Total of .The equilibration time of an autoclave is defined as the period of time that elapses between the attainment of the sterilization temperature at the reference measurement point of the autoclave chamber and the attainment of the sterilization temperature at all measurement probes within the dry goods load placed within the autoclave during a sterilization cycle. The equilibration time is . Today I will discuss a little about equilibration and lag times with respect to autoclave validation. I detail operational and performance qualification an.

how to calibrate digital refractometer

lag time in autoclave validation

how to calibrate milwaukee refractometer

Cycle development is an important part of both the autoclave procurement and validation processes. In previous posts about validation, we explored Installation Qualification (IQ), Operation Qualification (OQ), and Performance Qualification (PQ). We also discussed the importance of steam quality testing as part of validating your autoclave, as well as Factory .sterilization temperature and sterilizer time. The vast majority of loads sterilized in the laboratory setting are sterilized at 121.1°C/250°F for 30-90 minutes. For loads that are sensitive to heat, contact your autoclave validation expert for advice on calculating your sterilization time using the F0 relationship.Validating an autoclave is a daunting and time-consuming task. This white paper details the tricks, tips and traps to such a validation project from how to choose your control to which load . validation runs and all subsequent processing runs. T he cy cle is controlled v ia a liquid C O NT R O L and the steriliz ation time is determined by . Pressure must be with in 15 to 18 lbs maintain for 15 minutes, & find the lag time. 7.2.6 Heat distribution studies on maximum load of a load pattern three time by using a multi-point data logger. 7.2.7 All probes must reach temperature 121°C to 124°C. Pressure must be with in 15 to 18 lbs maintain for 15 minutes, and find the lag time.

Time and Temperature - F 0 “F sub O”: (continued) How is F 0 Calculated? The calculation of F 0 is based on a microorganism’s “D”-value and the corresponding “z”-value. The D-value is a measure of the heat resistance of a particular microorganism. The D .

Practical Guide to Autoclave Validation by Raymond G. Lewis, PE In addition to potential business liabilities, there can be significant costs associated with an autoclave validation process. The practical experience that this article is based on may provide assistance in ensuring an effective, efficient validation process for steam sterilization. T Inputting these data incrementally would allow the data acquisition system to calculate cumulative equivalent time for the full process, as well as for the shorter cycles used in D-value calculations. Product release criteria could then be established based on total equivalent time as established in the validation. Estimated Integration. Autoclave validation. Not only the qualification, but also the validation of the autoclave is regulated with regard to the procedure and set in several steps. Validation is understood to be proof that the autoclave achieves a sterilization process with reproducible results under operating conditions at the respective site. Accordingly, it .

The set temperature will achieve to equilibrium with all the probes in short time. The time at which the set temperature reaches equilibrium the hold time starts. It is generally set at above 121. In modern autoclave the holding time automatically starts once the equilibrium is achieved and this is validated frequently. Why Air Removal is Required in Autoclave?How to calculate F0 Value?What is Overkill Cycle in Steam Sterilization?#autoclavevalidation #Validation #Validation. Pressure must be with in 15 to 18 lbs maintain for 15 minutes, and find the lag time. 7.2.12 With the above heat penetration study the maximum lag time plus 15 minutes is regular operating cycle of the validated load pattern.7.2.13.1 Keep spores suspension of Bacillus Stearothermophilus of having population 10 6 at various location of the .

autoclave validation latency

involve in autoclave validation. if external agency is involved it will provide pre & post calibration certificate or at the time of completion of validation post calibration can be done at site also . 11.0 TESTS AND CHECKS: The autoclave will be considered validated on successful completion of the following tests.

The lag time, equal to the total time before the last domino falls, is the sum of the waiting times for every domino, analogous to a significant formation of fibril f n at t lag. Upon plotting the intermediate “locked” fibrils, the ‘domino effect’ is observed, showing that the lag time is equal to the sum of the timescales required for .

Calculation of D - Value, Z . F0-Value at a particular temperature other than 121ºC is the time in minutes required to provide the lethality equivalent to that provided at 121ºC for a stated time. . Formulas Related to Autoclave Validation. Fo = D121 ( logNo – log N )

3.0 Connect the probes to a suitable autoclave data logger, which can scan and print the actual temperature observed at different locations with respect to time. 4.0 Operate the steam sterilizer and also start the autoclave data logger to record actual temperature within the sterilization chamber with respect to time.Open the door of vertical autoclave and insert the 12 sensors through validation port into the chamber. Close the door of an Autoclave and connect the outputs of the 12 sensors to the Temperature Data logger. Set the temperature at 121.4°C and Sterilization hold time 30 minutes. Now start the cycle as per SOP.

how to calibrate my honey refractometer

A medical autoclave is a device that uses steam to sterilize equipment and other objects. This means that all bacteria, viruses, fungi, and spores are inactivated. However, prions, such as those associated with Creutzfeldt–Jakob disease, and some toxins released by certain bacteria, such as Cereulide, may not be destroyed by autoclaving at the typical 134 °C for three minutes or 121 °C for 1.

lag time calculation autoclave validation|autoclave steam sterilization lag time